When you think about the pharmaceutical industry, it’s easy to overlook the essential machinery behind drug production, but that’s where gearbox manufacturers come in. They provide the vital gear systems that ensure operations run smoothly and efficiently, contributing significantly to the overall effectiveness of production. This relationship between reliability and innovation raises some interesting questions about how these manufacturers adapt to industry demands. What challenges do they face in meeting stringent regulations while pushing technological boundaries? The answers might surprise you.

Importance of Gearboxes in Pharmaceuticals

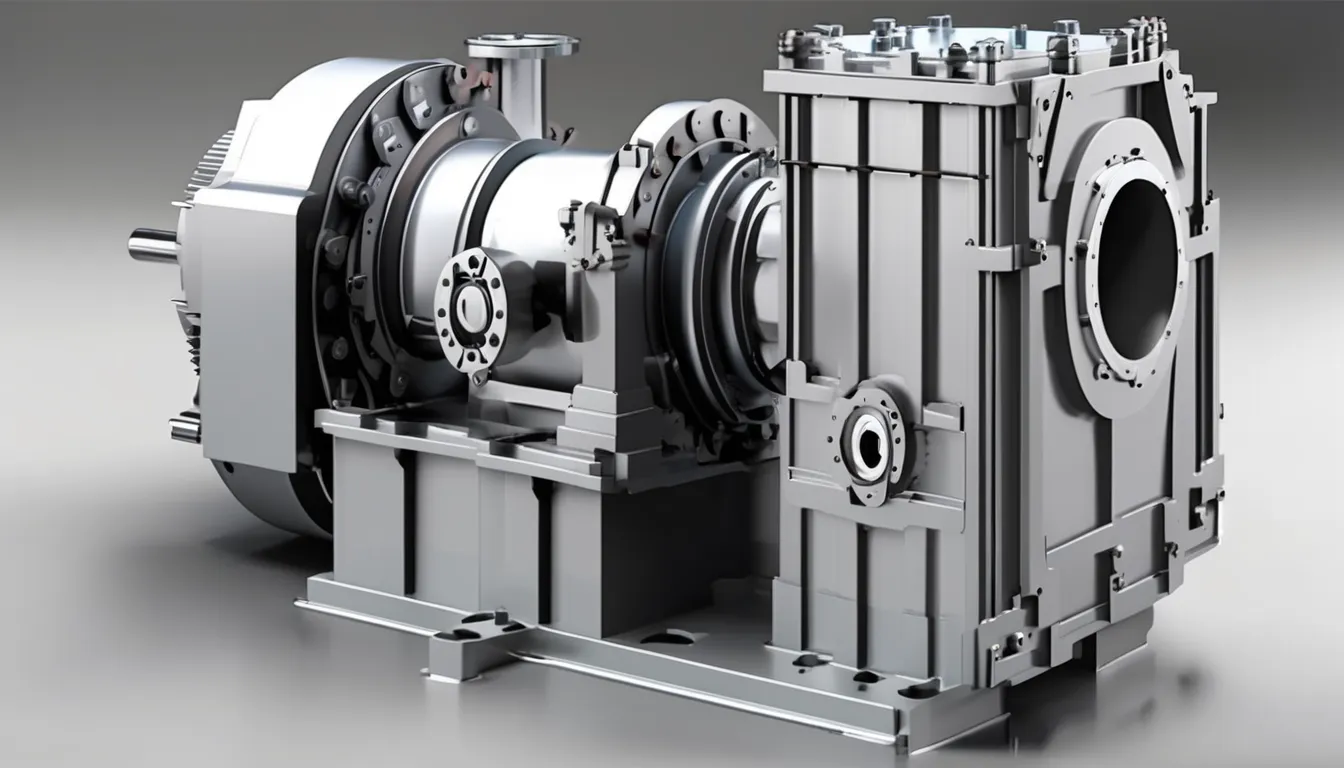

In the pharmaceutical industry, gearboxes play a crucial role in ensuring efficient and reliable operations. You mightn’t realize it, but these mechanical devices are at the heart of many processes, from mixing ingredients to packaging final products.

When you think about the intricate machinery used in drug manufacturing, gearboxes help transfer power and motion, enabling these systems to function smoothly. By converting the speed and torque from motors, gearboxes allow various equipment to operate at optimal levels.

Whether it’s a conveyor belt moving tablets or a mixer blending compounds, you depend on gearboxes to maintain the right speed and force. Their reliability directly impacts your production timelines and product quality.

Moreover, the pharmaceutical industry often requires precise control over operations. You’ll find that gearboxes provide this control, allowing for consistent results and reducing the risk of errors.

As regulations and standards tighten, your reliance on dependable gearboxes becomes even more important. Ultimately, understanding the importance of gearboxes in your processes can help you appreciate their role in delivering safe and effective medications to patients.

Key Functions of Gearbox Manufacturers

Gearbox manufacturers play a pivotal role in the pharmaceutical industry by designing and producing gear systems that meet specific operational needs.

You’ll find that their first key function is customizing gearboxes to fit unique applications, ensuring optimal performance in various manufacturing processes. This customization allows for efficient movement and control in machinery used for mixing, packaging, and transporting pharmaceutical products.

Another essential function is providing reliable and durable gear systems. You want equipment that can withstand the rigorous demands of the pharmaceutical environment, including high temperatures and pressures. Manufacturers focus on using high-quality materials and advanced engineering techniques to create gearboxes that last.

Additionally, gearbox manufacturers often offer comprehensive support services. They help with installation, maintenance, and troubleshooting, ensuring that your operations run smoothly. This support is crucial for minimizing downtime, which can be costly in the pharmaceutical sector.

Lastly, manufacturers keep abreast of industry advancements and technological innovations. By integrating the latest trends into their designs, they help you stay competitive in a rapidly evolving market.

With these functions, gearbox manufacturers are indispensable partners in your pharmaceutical operations.

Quality Standards and Compliance

Maintaining high quality standards and compliance is critical in the pharmaceutical industry, where even minor inconsistencies can lead to serious consequences.

As a gearbox manufacturer, you play a vital role in ensuring that your products meet rigorous regulatory requirements. Here are some key aspects you need to focus on:

- Regulatory Compliance: Familiarize yourself with regulations such as FDA, cGMP, and ISO standards that govern pharmaceutical manufacturing processes.

- Material Integrity: Ensure that the materials used in your gearboxes are pharmaceutical-grade and resistant to corrosion and contamination, which can affect product quality.

- Quality Control Processes: Implement robust quality control measures, including regular testing and validation of your gearbox components to guarantee performance and reliability.

- Documentation and Traceability: Maintain clear and comprehensive records of your manufacturing processes, materials used, and testing results to provide traceability and accountability.

Innovations in Gearbox Technology

Recent advancements in gearbox technology are transforming the pharmaceutical industry, enhancing efficiency and reliability.

You’ll notice that manufacturers are increasingly adopting innovative designs, such as modular gear systems that allow for quick replacements and reduced downtime. These systems can be easily customized to meet specific operational needs, ensuring optimal performance in various applications.

Another key innovation is the integration of smart technology into gearboxes. With sensors and IoT capabilities, these gearboxes can monitor real-time performance data, helping you identify potential issues before they become major problems.

This proactive approach not only minimizes maintenance costs but also maximizes production uptime.

Additionally, advancements in materials have led to lighter, stronger gearboxes that withstand the demanding conditions of pharmaceutical processes.

These materials reduce wear and tear, ultimately extending the lifespan of the equipment.

Challenges Facing Gearbox Manufacturers

As innovative designs and smart technologies revolutionize the pharmaceutical sector, gearbox manufacturers face a unique set of challenges.

You’ll find that keeping pace with rapid advancements is essential, but it’s not without hurdles. Here are some key challenges you should be aware of:

- Regulatory Compliance: The pharmaceutical industry is heavily regulated. Gearbox manufacturers must ensure their products meet stringent standards, which can slow down development and increase costs.

- Customization Demand: With the rise of personalized medicine, there’s a growing need for customized equipment. This requires flexibility in design and manufacturing processes, which can strain resources.

- Supply Chain Disruptions: Global supply chains are often unpredictable. Material shortages or delays can hinder production schedules and affect delivery timelines.

- Technological Integration: As the industry moves towards automation and digitalization, china gearbox manufacturer manufacturers must integrate advanced technologies.

This transition requires significant investment and expertise, which can be challenging to acquire.

Conclusion

In conclusion, gearbox manufacturers are vital to the pharmaceutical industry, ensuring efficient and reliable operations. Their commitment to quality standards and innovative technologies helps meet the rigorous demands of drug manufacturing. By understanding the challenges they face, you can appreciate their role in optimizing performance and maintaining production timelines. As the industry evolves, staying informed about advancements in gearbox technology will be essential for enhancing product quality and overall operational efficiency.