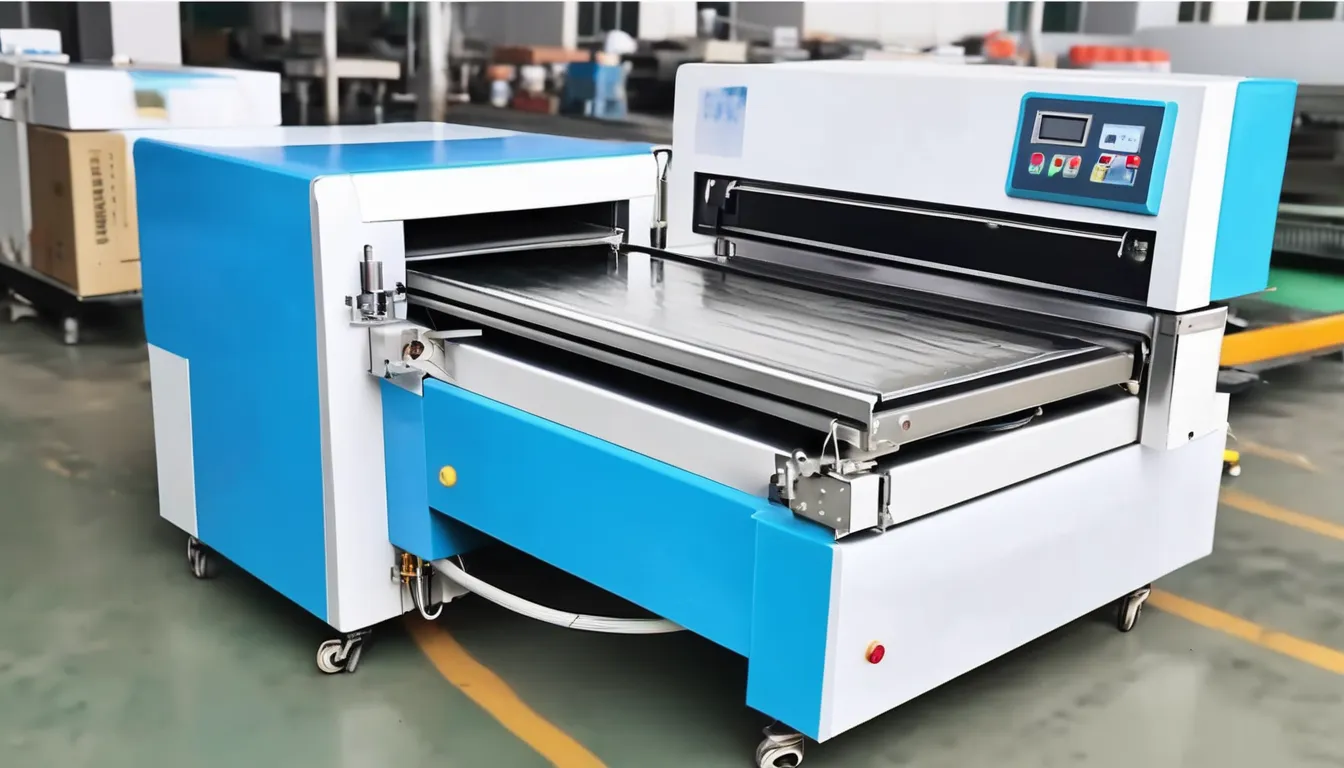

Horizontal wrapping machines play a crucial role in the packaging industry, offering a range of benefits that can significantly impact your production process. From optimizing efficiency to ensuring product safety, these machines are a must-have tool for any packaging operation. But there’s more to their importance than meets the eye. Consider how these machines can revolutionize your packaging approach and elevate your overall business performance.

Increased Efficiency in Packaging

When it comes to packaging with horizontal wrapping machines, efficiency is key. These machines are designed to streamline the packaging process, saving you time and resources. By automating the wrapping process, you can significantly increase your packaging speed, ensuring that your products are ready for distribution in a timely manner.

With horizontal wrapping machines, you can achieve consistent and professional packaging results with minimal manual labor required.

One of the key benefits of using horizontal wrapping machines is their ability to handle a wide range of products and package sizes. Whether you’re packaging food items, household goods, or industrial products, these machines can adapt to accommodate different shapes and sizes with ease. This flexibility not only saves you time but also allows for greater versatility in your packaging operations.

In addition to efficiency, horizontal wrapping machines also offer reliability and consistency in packaging. By reducing human error and ensuring uniform packaging results, these machines help maintain the quality of your products and uphold your brand reputation.

Enhanced Product Protection

To ensure the integrity and safety of your products during the packaging process, enhanced product protection is a crucial aspect to consider when utilizing horizontal wrapping machines. Here are four key reasons why enhanced product protection is essential:

- Minimizes Damage: Horizontal wrapping machines provide a secure and stable wrapping process, reducing the risk of product damage during transit or storage.

- Protects Against Contaminants: By tightly wrapping products, horizontal wrapping machines help shield items from dust, moisture, and other contaminants that could compromise product quality.

- Prevents Tampering: The sealed wrapping created by horizontal machines acts as a deterrent to tampering, ensuring that products reach customers in the intended condition.

- Enhances Shelf Life: With enhanced protection from external elements, products wrapped using horizontal machines can have an extended shelf life, maintaining freshness and quality for longer periods.

Cost-Effective Packaging Solution

Opting for horizontal wrapping machines as your packaging solution offers a cost-effective method that streamlines your production process. These machines are designed to efficiently wrap products in a horizontal motion, reducing material waste and ensuring consistent wrapping results. By investing in a horizontal wrapping machine, you can save on labor costs as these machines are automated and require minimal human intervention.

Additionally, the speed and precision of horizontal wrapping machines contribute to increased productivity, allowing you to package more products in less time.

Moreover, horizontal wrapping machines are versatile and can handle a variety of product sizes and shapes, eliminating the need for multiple packaging solutions. This versatility not only saves you money on purchasing different machines but also reduces maintenance costs and training expenses.

Improved Visual Presentation

For companies seeking to enhance the visual appeal of their packaged products, horizontal wrapping machines offer a solution that goes beyond mere functionality. With these machines, you can achieve a polished and professional look for your products, leaving a lasting impression on your customers.

Here are four key ways in which horizontal wrapping machines can help improve the visual presentation of your packaged goods:

- Consistent Wrapping: Horizontal wrapping machines ensure that each item is wrapped uniformly, creating a cohesive and neat appearance across all your products.

- Customizable Packaging: These machines allow for the customization of packaging designs, enabling you to showcase your brand logo, colors, and product information prominently.

- Protective Wrapping: By securely wrapping your products in a horizontal fashion, you not only enhance their visual appeal but also provide protection against damage during transit.

- Tamper-Evident Packaging: Horizontal wrapping machines can incorporate tamper-evident features, assuring customers of the product’s safety and integrity.

Streamlined Packaging Operations

With horizontal wrapping เครื่องซีลสายพาน , your packaging operations can be streamlined to optimize efficiency and productivity. These machines offer a seamless process that reduces manual labor and speeds up packaging tasks. By automating the wrapping process, you can save valuable time and resources, allowing your staff to focus on other essential tasks.

The streamlined operations provided by horizontal wrapping machines also help in maintaining consistency in packaging quality. With precise wrapping and sealing mechanisms, these machines ensure that every product is packaged securely and uniformly, enhancing the overall presentation of your goods.

Furthermore, the efficiency of horizontal wrapping machines leads to increased output and faster turnaround times. This can be especially beneficial during peak seasons or when handling large volumes of products.

Frequently Asked Questions

Can Horizontal Wrapping Machines Handle Various Product Shapes and Sizes?

Yes, horizontal wrapping machines can handle various product shapes and sizes. They offer versatility and efficiency in packaging different items. You’ll find that these machines are designed to accommodate a wide range of products with ease.

What Maintenance Requirements Are Needed for Horizontal Wrapping Machines?

To keep your horizontal wrapping machine running smoothly, regularly clean and lubricate moving parts, inspect for wear and tear, and follow manufacturer’s maintenance schedule. This ensures optimal performance and prolongs the machine’s lifespan.

Are There Specific Industries That Benefit Most From Horizontal Wrapping Machines?

Various industries benefit greatly from horizontal wrapping machines. You’ll find them widely used in food, pharmaceuticals, printing, and more. These machines streamline packaging processes, improve efficiency, and ensure product protection during transport.

What Are the Energy Consumption Levels of Horizontal Wrapping Machines?

Horizontal wrapping machines have varying energy consumption levels based on their size and features. You should consider the specific model you’re interested in for accurate information. Researching different options will help you make an informed decision.

How Do Horizontal Wrapping Machines Integrate With Existing Packaging Systems?

When integrating horizontal wrapping machines with existing systems, you’ll find they streamline packaging processes by efficiently wrapping products. They are versatile, saving time and labor costs. Consider their adaptability to enhance your packaging efficiency.

Conclusion

In conclusion, horizontal wrapping machines are a packaging essential for their ability to increase efficiency, enhance product protection, and provide cost-effective solutions. They streamline operations, improve visual presentation, and ensure product integrity and safety. By automating wrapping, reducing material waste, and cutting labor costs, these machines offer significant benefits to packaging operations. Invest in a horizontal wrapping machine to optimize your packaging process and achieve consistent, high-quality results.