When you’re in the market for a reducer manufacturer, it’s crucial to focus on quality to ensure you get a product that meets your needs. You should examine the materials they use, like steel or aluminum, which play a significant role in durability. It’s also worth considering their manufacturing processes and whether they hold industry certifications. But don’t stop there; understanding the manufacturer’s reputation and customer support can make all the difference. What factors will truly set one manufacturer apart from another, and how can you identify those key elements?

Material Quality and Durability

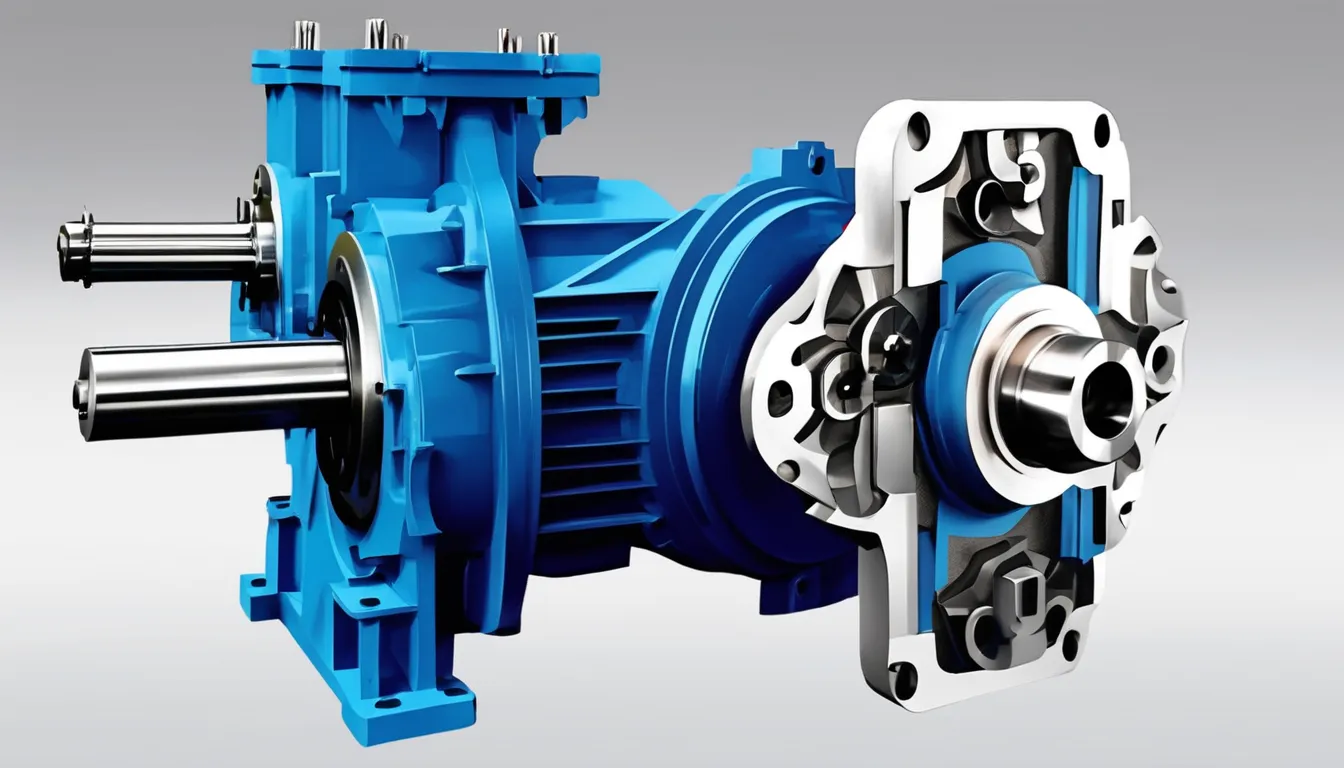

When selecting a reducer manufacturer, material quality and durability should be at the forefront of your decision-making process. You need to ensure that the materials used in the reducers can withst Reducer Manufacturer the specific demands of your application. High-quality materials not only enhance performance but also extend the lifespan of the equipment, saving you money in the long run.

Look for manufacturers that utilize premium materials like steel or aluminum, as these can offer superior strength and resistance to wear and corrosion.

It’s also essential to consider the manufacturer’s reputation in the industry. Research customer reviews and testimonials to gauge their reliability and product performance.

Don’t hesitate to ask for certifications or quality assurance processes the manufacturer follows. This information can give you peace of mind that you’re investing in a product that meets industry standards.

Manufacturing Processes

In choosing a reducer manufacturer, understanding their manufacturing processes is crucial for ensuring you get a reliable product. You should look for manufacturers that utilize advanced technology and automation in their production lines. This not only enhances precision but also improves consistency across batches.

Pay attention to the types of machining processes they employ, such as CNC (Computer Numerical Control) machining, which offers high accuracy in producing components.

It’s also essential to consider their assembly processes. A manufacturer that follows strict assembly protocols is more likely to deliver a well-constructed reducer.

Another aspect to evaluate is their quality control measures. Ask about their inspection techniques and testing methods to ensure each product meets the required specifications. A comprehensive quality assurance program indicates a commitment to excellence.

Additionally, consider the flexibility of their manufacturing processes. Can they accommodate custom designs or modifications? This adaptability can be a significant advantage for your specific application needs.

Ultimately, choosing a manufacturer that demonstrates robust and efficient manufacturing processes will give you confidence in the reliability and performance of your reducer.

Industry Certifications

A manufacturer’s adherence to industry certifications can significantly impact the quality and reliability of the reducers they produce. When you’re evaluating a potential manufacturer, look for certifications such as ISO 9001, which indicates they follow strict quality management systems. This certification ensures consistency in their processes, leading to reliable products.

Another important certification is the CE mark, particularly if you’re dealing with European markets. This mark shows that the product complies with EU safety and environmental standards, giving you peace of mind that you’re investing in a safe product.

Additionally, check for any industry-specific certifications that might apply to your application, such as those from the American Gear Manufacturers Association (AGMA) or the National Electrical Manufacturers Association (NEMA).

These certifications serve as a quality assurance benchmark, ensuring the manufacturer meets established industry standards. By choosing a manufacturer with the right certifications, you’re not just buying a product; you’re investing in reliability and performance.

Ultimately, confirming these credentials can save you time and money in the long run, as it minimizes the risk of product failure and enhances the overall efficiency of your operations.

Customer Support and Service

Choosing the right reducer manufacturer isn’t just about the product itself; it also hinges on the quality of customer support and service you can expect. When you invest in a reducer, you want to know that help is just a phone call away. A manufacturer that prioritizes customer support demonstrates their commitment to your satisfaction and success.

Look for a company that offers multiple channels for communication, such as phone, email, and live chat. It’s crucial that you can reach them easily, especially in urgent situations. Response times matter too; a manufacturer who replies quickly shows they value your business.

Consider whether they provide comprehensive support resources, like user manuals, FAQs, and troubleshooting guides. These can save you time and frustration. Additionally, check if they offer training or assistance with installation and maintenance.

Don’t underestimate the importance of after-sales support. Should you encounter issues with your reducer, you’ll want a manufacturer that’s ready to resolve problems efficiently.

Reputation and Reviews

When selecting a reducer manufacturer, the company’s reputation and customer reviews play a crucial role in your decision-making process. A strong reputation often indicates reliability and quality, while customer reviews can provide insights into real-world experiences with the product and the manufacturer.

To help you assess potential manufacturers, consider the following factors:

| Factor | What to Look For | Why It Matters |

|---|---|---|

| Industry Reputation | Established history | Trustworthy manufacturers often have a proven track record. |

| Customer Feedback | High ratings and reviews | Positive experiences can indicate product reliability and service quality. |

| Awards and Certifications | Recognition in the industry | Awards can signify excellence in manufacturing and innovation. |

Check online platforms, industry forums, and social media for unbiased reviews. Don’t hesitate to ask for references from the manufacturer to gain further insights. Ultimately, a well-regarded manufacturer with positive reviews can give you confidence in your choice, ensuring that you’re investing in quality and reliability for your projects.

Conclusion

When choosing a reducer manufacturer, you can’t overlook the importance of quality. Focus on materials like steel or aluminum for durability, and make sure they use advanced manufacturing processes like CNC machining. Don’t forget to check for industry certifications and pay attention to customer reviews. A strong reputation and reliable support can make all the difference. By prioritizing these factors, you’ll ensure you’re investing in a high-quality reducer that meets your needs effectively.