When you consider efficiency in industrial applications, gear pumps often come to mind as a reliable solution. They offer consistent flow rates and can handle high-viscosity fluids, making them versatile across various sectors. Their design ensures minimal maintenance and long service life, which can translate into significant cost savings. As you explore the key advantages of gear pumps, you might find yourself questioning how these benefits align with your specific operational needs. Understanding their applications in different industries can reveal even more about their value.

Overview of Gear Pumps

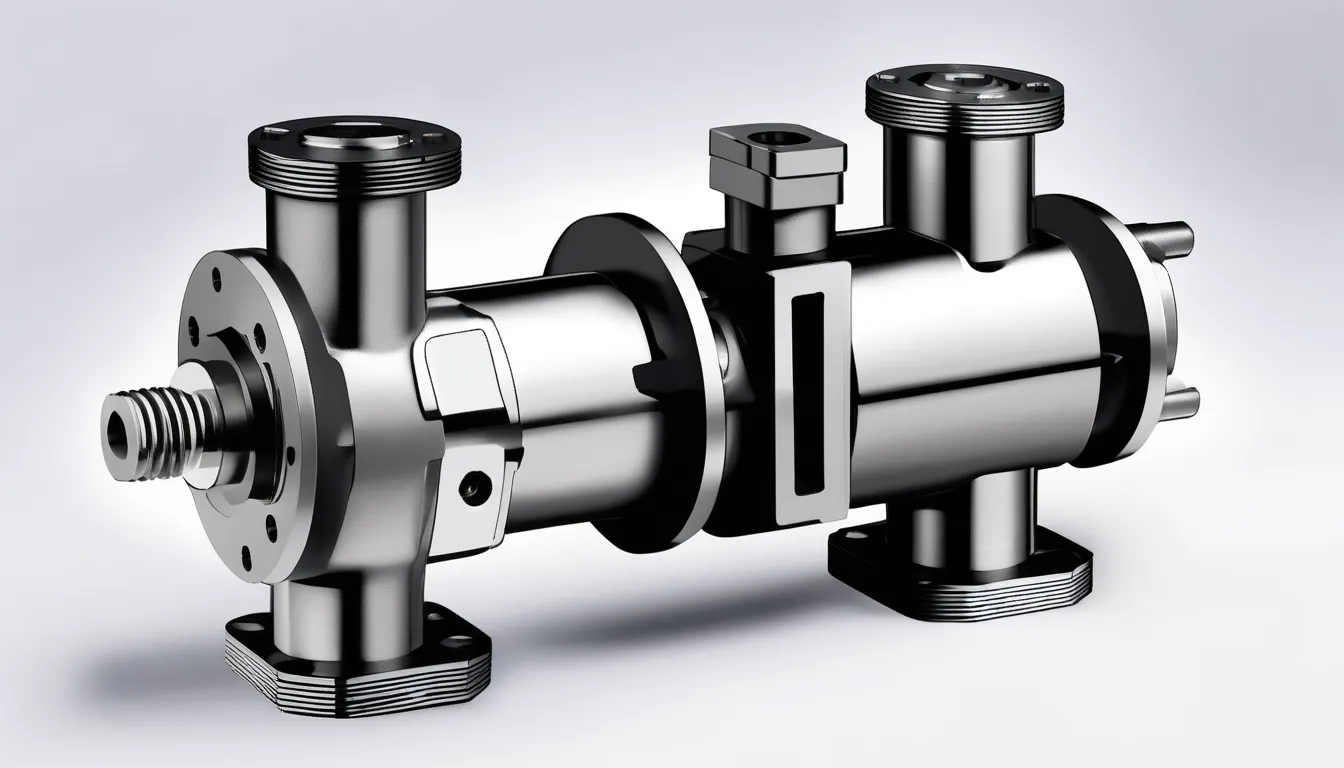

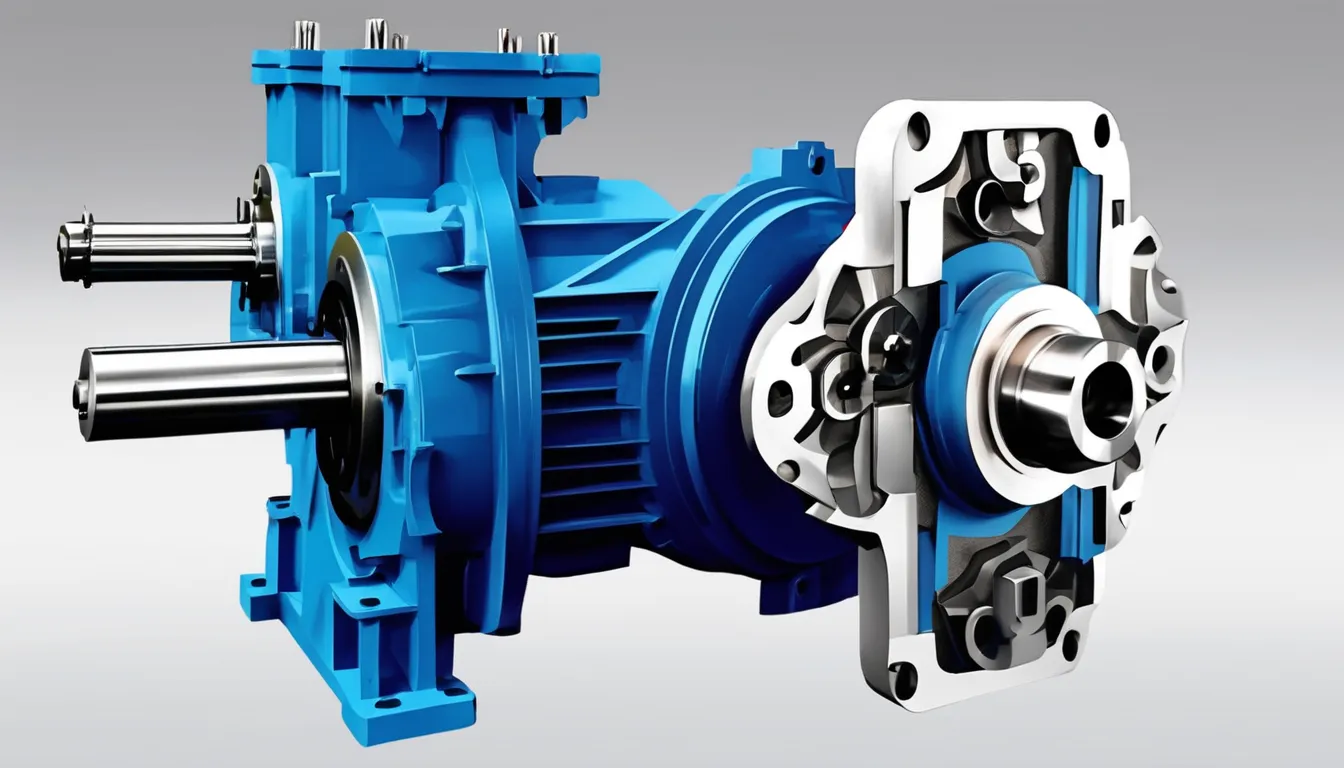

Gear pumps play a crucial role in various industrial applications, efficiently transferring fluids with precision. These positive displacement pumps use meshing gears to move fluid through the system, creating a consistent flow regardless of pressure changes. You’ll often find gear pumps in hydraulic systems, lubrication applications, and chemical processing, where reliability is key.

When you look at their design, gear pumps consist of two or more gears that rotate within a casing. As the gears turn, they trap fluid in the spaces between them and push it through the discharge port. This mechanism ensures a smooth and steady flow, making gear pumps particularly effective for high-viscosity fluids.

You might also notice that gear pumps come in different types, such as external and internal gear pumps, each serving varied needs. Their compact size and straightforward design make them easy to integrate into existing systems.

Plus, they require minimal maintenance, which saves you time and money in the long run. Overall, understanding how gear pumps work can help you appreciate their significance in the industrial landscape, ensuring efficient and reliable fluid transfer for a wide range of applications.

Key Advantages of Gear Pumps

Recognizing the unique benefits of gear pumps can greatly enhance your decision-making in fluid transfer applications.

These pumps are known for their reliability and efficiency, making them an excellent choice for various industrial needs. Here are four key advantages you should consider:

- Consistent Flow Rate: Gear pumps deliver a steady flow of fluid, which is crucial for processes requiring precise measurements and consistent performance.

- High Pressure Capability: They can handle high-pressure applications with ease, making them ideal for moving viscous fluids and operating in demanding environments.

- Durability and Longevity: Constructed from robust materials, gear pumps are designed to withstand wear and tear, ensuring a longer lifespan and lower maintenance costs.

- Compact Design: Their space-efficient design allows for easy installation in tight spaces, which is often necessary in modern industrial settings.

Applications in Various Industries

In numerous industrial settings, gear pumps play a vital role in fluid transfer, ensuring efficiency and reliability across various applications.

You’ll find them in the oil and gas industry, where they handle crude oil, refined fuels, and lubricants. Their ability to manage high-viscosity fluids makes them indispensable in these high-demand environments.

In the chemical processing sector, gear پمپ دنده ای s are crucial for transferring corrosive and viscous liquids. Their precise flow rates help maintain stringent process control, ensuring consistent quality.

If you’re in the food and beverage industry, you’ll appreciate gear pumps for their hygienic design, allowing for the safe transfer of products like syrups, oils, and sauces without contamination.

Pharmaceutical manufacturers also rely on gear pumps for their ability to handle sensitive liquids with care. In these settings, maintaining product integrity is vital, and gear pumps excel in providing gentle yet effective transfer.

Maintenance and Longevity

When it comes to maintaining gear pumps, paying close attention to their components is essential for ensuring longevity and optimal performance.

Regular maintenance can prevent breakdowns and extend the life of your gear pump, allowing it to operate efficiently in demanding industrial environments.

Here are four key maintenance tasks you should prioritize:

- Regular Inspections: Check for any signs of wear or damage. Early detection can save you from costly repairs later.

- Fluid Levels: Keep an eye on the hydraulic fluid levels and quality. Low or contaminated fluid can lead to pump failure.

- Clean Filters: Ensure that the filters are clean and free from debris. Clogged filters can restrict flow and reduce performance.

- Lubrication: Properly lubricate moving parts to minimize friction. This not only enhances efficiency but also reduces the risk of overheating.

Choosing the Right Gear Pump

Selecting the right gear pump for your industrial application is crucial for efficiency and reliability. Start by identifying the specific fluid you’ll be pumping. Consider its viscosity, temperature, and whether it contains any solids. These factors will determine the type of gear pump that best suits your needs.

Next, think about the required flow rate and pressure. Make sure to choose a pump that can handle your system’s demands without overloading or underperforming.

You’ll also want to evaluate the pump’s material construction. Ensure it’s compatible with the fluids being handled to prevent corrosion or wear.

Don’t forget to consider the installation space and orientation. Some gear pumps are more flexible in terms of positioning than others.

Maintenance accessibility is another important aspect; select a model that allows for easy service to minimize downtime.

Lastly, review the manufacturer’s reputation and warranty. A reliable brand will often provide better support and longer-lasting products.

Conclusion

In conclusion, gear pumps are essential for efficient fluid transfer in industrial applications. Their ability to handle high-viscosity fluids with precision makes them invaluable across various sectors. By understanding their advantages, applications, and maintenance needs, you can make informed decisions that enhance your operations. When you choose the right gear pump, you’re investing in reliability and performance that can lead to significant cost savings in the long run. Don’t underestimate their impact on your industrial processes!